What is a confined space?

Contents

- 1 What is a confined space?

- 2 What are the hazards in a confined space?

- 3 Why is working in a confined space more hazardous than working in other workspaces?

- 4 What should be done when preparing to enter the confined space?

- 5 What should happen when work is being done in a confined space?

- 6 Checklist

- 7 What are some emergency response precautions?

- 8 Checklist

- 9 Is worker training important?

- 10 What are other safety precautions?

- 11 What is an Entry Permit System?

- 12 Standby/Rescue

- 13 RECOMMENDATIONS FOR SAFE ENTRY: A CHECKLIST

- 14 Glossary – Confined Space Safety

Generally speaking, a confined space is an enclosed or partially enclosed space that:

- is not primarily designed or intended for human occupancy,

- has a restricted entrance or exit by way of location, size or means,

- can represent a risk for health and safety of anyone who enters, due too one or more of the following factors:

– Its design, construction, location or atmosphere,

– the materials or substances in it,

– work activities being carried out in it, or the

– mechanical, process and safety hazards present.

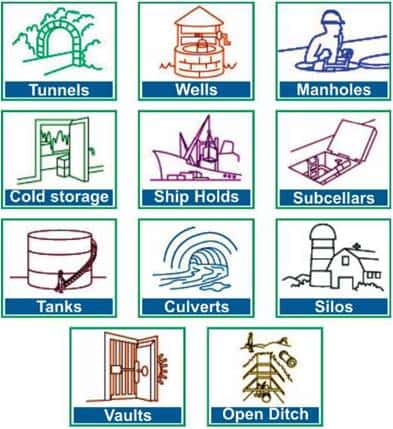

Confined spaces can be below or above ground. Confined spaces can be found in almost any workplace. A confined space, despite its name, is not necessarily small. Examples of confined spaces include silos, vats, hoppers, ESPs, reaction vessels, utility vaults, tanks, sewers, pipes, access shafts, truck or rail tank cars, aircraft wings. Ditches and trenches may also be a confined space when access or egress is limited.

What are the hazards in a confined space?

All hazards found in a regular workspace can also be found in a confined space. However, they can be even more hazardous in a confined space than in a regular work site.

Hazards in confined spaces can include the following, for example:

- Poor air quality: There may be an insufficient amount of oxygen for the worker to breathe. The atmosphere might contain a poisonous substance that could make the worker ill or even cause the worker to lose consciousness. Natural ventilation alone will often not be sufficient to maintain breathable quality air

- Chemical exposures due to skin contact or ingestion as well as inhalation of ’bad’ air

- Fire Hazard: There may be an explosive/inflammable atmosphere due to inflammable liquids and gases and combustible dusts which, if ignited, would lead to fire or explosion

- Process-related hazards such as residual chemicals, release of contents of a supply line

- Noise

- Safety hazards such as moving parts of equipment, structural hazards, entanglement, slips, falls, etc.

- Radiation

- Temperature extremes including atmospheric and surface

- Shifting or collapse of bulk material

- Barrier failure resulting in a flood or release of free-flowing solid

- Uncontrolled energy including electrical shock

- Visibility

- Biological hazards

Department. of Factories, Boilers, Industrial Safety & Health, Karnataka

Why is working in a confined space more hazardous than working in other workspaces?

Many factors need to be evaluated when looking for hazards in a confined space. There is smaller margin for error. An error in identifying or valuating potential hazards can have more serious consequences. In some cases, the conditions in a confined space are always extremely hazardous. In other cases, conditions are life threatening under an unusual combination of circumstances. Due to this variability and unpredictability, the hazard assessment is extremely important and must be taken very seriously each and every time.

Some examples include:

- The entrance/exit of the confined space might not allow the worker to get out in time should there be a flood or collapse of free-flowing solid.

- Rescue of the victim is more difficult. The interior configuration of the confined space often does not allow easy movement of people or equipment within it.

- Self-rescue by the worker is more difficult.

- Natural ventilation alone will often not be sufficient to maintain breathing quality air. The interior configuration of the confined space does not allow easy movement of air within it.

- Conditions can change very quickly.

- The space outside the confined space can impact on the conditions inside the confined space and vice versa.

- Work activities may introduce hazards not present initially.

One should not ignore the following:

Oxygen-deficient atmosphere

An oxygen-deficient atmosphere has less than 19.5% available oxygen (02). Any atmosphere with less than 19.5% oxygen should not be entertained without an approved self-contained breathing apparatus (SCBA).

The oxygen level in a confined space can be decreased because of work being done, such as welding, cutting, or brazing; or, it can be decreased by certain chemical reactions (rusting) or through bacterial action (fermentation).

The oxygen level is also decreased if oxygen is displaced by another gas, such as carbon dioxide or nitrogen. Total displacement of oxygen by another gas, such as carbon dioxide, will result in unconsciousness, followed by death.

Flammable atmosphere

Two things make an atmosphere inflammable: 1) the oxygen in air; and 2) a inflammable gas, vapour, or dust in the proper mixture. Different gases have different inflammable ranges. If a source of ignition (e.g., a sparking or electrical tool) is introduced into a space containing a inflammable atmosphere, an explosion will result.

An oxygen-enriched atmosphere (above 21%) will cause inflammable materials, such as clothing and hair, to burn violently when ignited. Therefore, never use pure oxygen to ventilate a confined space. Ventilate with normal air.

Types of major chemical/industrial hazards – Fire

Toxic atmospheres

Most substances (liquids, vapours, gases, mists, solid materials, and dusts) should be considered hazardous in a confined space. Toxic substances can come from the following:

The product stored in the space:

The product can be absorbed into the walls and give off toxic gases, when removed or when cleaning out the residue of a stored product, toxic gases can be given off. Example: Removal of sludge from a tank – decomposed material can give off deadly hydrogen sulfide gas.

The work being performed in a confined space:

Examples of such include welding, cutting, brazing, painting, scraping, sanding, degreasing, etc. Toxic atmospheres are generated in various processes. For example, cleaning solvents are used in many industries for cleaning/degreasing. The vapors from these solvents are very toxic in a confined space.

Areas adjacent to the confined space:

Toxicants produced by work in the area of confined spaces can enter and accumulate in confined spaces.

What should be done when preparing to enter the confined space?

The important thing to remember is that each time a worker plans to enter any work space, the worker should determine if that work space is considered a confined space. Be sure that the confined space hazard assessment and control program has been followed.

The next question to ask is – Is it absolutely necessary that the work be carried out inside the confined space? In many cases where there have been deaths in confined spaces, the work could have been done outside the confined space.

Before entering any confined space, a trained and experienced person should identify and evaluate all the potential hazards within the confined space. An important step in determining the hazards in a confined space is air testing.

Factors Influencing Human Behaviour

Air quality testing

The air within the confined space should be tested from outside of the confined space before entry into the confined space. Care should be taken to ensure that air is tested throughout the confined space – side-to-side and top to bottom. A trained worker using detection equipment which has remote probes and sampling lines should do the air quality testing. The sampling should show that:

- The oxygen content is within safe limits – not too little and not too much.

- A hazardous atmosphere (toxic gases, flammable atmosphere) is not present.

- Ventilation equipment is operating properly.

The results of the tests for these hazards are to be recorded on the Entry Permit along with the equipment or method(s) that were used in performing the tests.

Air testing may need to be ongoing depending on the nature of the potential hazards and the nature of the work. Conditions can change while workers are inside the confined space and sometimes a hazardous atmosphere is created by the work activities in the confined space.

It is important to understand that some gases or vapours are heavier than air and will settle to the bottom of a confined space. Also, some gases are more light, than air and will be found around the top of the confined space. Therefore, it is necessary to test all areas (top, middle, bottom) of a confined space with properly calibrated testing instruments to determine which gases are present. If testing reveals oxygen-deficiency, or the presence of toxic gases or vapours, the space must be ventilated and re-tested before workers enter. If ventilation is not possible and entry is necessary (for emergency rescue, for example), workers must have appropriate respiratory protection.

Strategies for reducing human error

How are hazards controlled in confined spaces?

The traditional hazard control methods found in regular work sites can be effective in a confined space. These include engineering controls, administrative controls and personal protective equipment. Engineering controls are designed to remove the hazard while administrative controls and personal protective equipment try to minimize the contact with the hazard.

However, often because of the nature of the confined space and depending on the hazard, special precautions not normally required in a regular work site may also need to be taken. The engineering control commonly used in confined spaces is mechanical ventilation. The Entry Permit system is an example of an administrative control used in confined spaces. Personal protective equipment (respirators, gloves, ear plugs) is commonly used in confined spaces as well.

How is air quality maintained?

Natural ventilation (natural air currents) is usually not reliable and sufficient to maintain the air quality. Mechanical ventilation (blowers, fans) is usually necessary to maintain air quality.

- If mechanical ventilation is provided, there should be a warning system in place to immediately notify the worker in the event of a hazard or a failure in the ventilation equipment.

- Care should be taken to make sure the air being provided by the ventilation system to the confined space is ’clean’.

- Ease of air movement throughout the confined space should be considered, because of the danger of pockets of toxic gases still remains even with the use of mechanical ventilation.

- Do not substitute oxygen for fresh air. Increasing the oxygen content will significantly increase the risk of fire and explosion.

- The use of mechanical ventilation should be noted on the entry permit.

The following paragraphs provide information on ventilation, isolation and respirators. All these are important for air quality maintenance and safety of workers. All these are monitored and regulated as per regulations of industrial health and hygiene.

Ventilation

Ventilation by a blower or fan may be necessary to remove harmful gases and vapours from a confined space. There are several methods for ventilating a confined space. The method and equipment chosen are dependent upon the size of the confined space openings, the gases to be exhausted (e.g., are they flammable?), and the source of makeup air.

Under certain conditions where in flammable gases or vapours have displaced the oxygen level, but are too rich to burn, the forced air ventilation may dilute them until they are within the explosive range. Also, if inert gases (e.g. carbon dioxide, nitrogen, argon) are used in the confined space, the space should be well ventilated and re-tested before a worker enters.

A common method of ventilation requires a large hose, one end attached to a fan and the other lowered into a manhole or opening. For example, a manhole would have the ventilating hose run to the bottom to blow out all harmful gases and vapours (see diagram). The air intake should be placed in an area that will draw in fresh air only. Ventilation should be continuous where possible, because in many confined spaces the hazardous atmosphere will be formed again when the flow of air is stopped.

Isolation

Isolation of a confined space is a process where the space is removed from service by:

- Locking out by electrical sources, preferably at disconnected switches remote from the equipment.

- Blanking and bleeding pneumatic and hydraulic lines.

- Disconnecting belt and chain drives, and mechanical linkages on shaft-driven equipment where possible.

- Securing mechanical moving parts within confined spaces with latches, chains, choke, blocks, or other devices.

- Locking out by electrical sources, preferably at disconnected switches remote from the equipment.

- Blanking and bleeding pneumatic and hydraulic lines.

- Disconnecting belt and chain drives, and mechanical linkages on shaft-driven equipment where possible.

- Securing mechanical moving parts within confined spaces with latches, chains, choke, blocks, or other devices.

Respirators

Respirators are devices that can allow workers to safely breathe without inhaling toxic gases or particles. Two basic types are air-purifiers, which filter dangerous substances from the air, and air-suppliers, which deliver a supply of safe breathing air from a tank or an uncontaminated area nearby.

Selecting the proper respirator for the job, the hazard, and the person is very important, as is thorough training in the use and limitations of respirators. Questions regarding the proper selection and use of respirators should be addressed to a certified industrial hygienist, or to the NIOSH Division of Safety Research, 944 Chestnut Ridge Rd., Morgantown, West Virginia 26505.

What is Heinrich’s Domino Theory? What Causes Accidents

How are fire and explosion prevented?

Work where a flame is used or a source of ignition may be produced (hot work) should not normally be performed in a confined space unless:

- All in flammable gases, liquids and vapours are removed prior to the start of any hot work. Mechanical ventilation is usually used to

– keep the concentration of any explosive or flammable hazardous substance

– less than 10% of its Lower Explosive Limit

– make sure that the oxygen content in the confined space is not enriched.

– Oxygen content should be less than 23% but maintained at levels greater than 18%. (These numbers can vary slightly from jurisdiction to jurisdiction.)

- Surfaces coated with combustible material should be cleaned or shielded to prevent ignition.

While doing the hot work, the concentrations of oxygen and combustible materials must be monitored to make certain that the oxygen levels remain in the proper range and the levels of the combustible materials do not get higher than 10% of the Lower Explosive Limit. In special cases it may not be possible, and additional precautions must be taken to ensure the safety of the worker prior to entering the confined space.

How are energy sources controlled?

All potentially hazardous energy sources must be de-energized and locked out prior to entry to the confined space so that equipment cannot be turned on accidentally.

Checklist

| YES | NO | |

|---|---|---|

| Is entry necessary? |

| YES | NO | TESTING |

|---|---|---|

| Are the instruments used in atmospheric testing properly calibrated? | ||

| Was the atmosphere in the confined space tested? | ||

| Was Oxygen at least 19.5% – not more than 21%? | ||

| Were toxic, flammable, or oxygen-displacing gases/vapours present? |

| Which of the following gases are identified? | |

|---|---|

| Hydrogen Sulfide | |

| Carbon Monoxide | |

| Methane | |

| Carbon Dioxide | |

| Other (list) | |

What should happen when work is being done in a confined space?

There should be warning signs to prevent unauthorized entry to the confined space.

Anyone working in a confined space must be constantly alert for any changing conditions within the confined space. In the event of an alarm from monitoring equipment or any other indication of danger, workers should immediately leave the confined space.

Another device, the Safety Watch or Standby, is posted outside the confined space and continuously monitor the workers inside the confined space. The Safety Watch has the following duties:

- Understands the nature of the hazards that may be found inside the particular confined space and can recognize signs, symptoms and behavioral effects that workers in the confined space could experience.

- Monitors the confined space and surrounding area and is on the look out for dangerous conditions.

- Remains outside the confined space and does no other work which may interfere with their primary duty of monitoring the workers inside the confined space.

- Maintains constant communication with the workers in the confined space.

- Orders the immediate evacuation if a potential hazard, not already controlled for, is detected.

- Calls for emergency assistance immediately if an emergency develops.

- Is immediately available to provide non-entry emergency assistance when needed.

- Can provide entry rescue only after the most stringent precautions are taken and another Safety Watch is immediately available.

Should a worker leave a confined space for a short time (for example, coffee break, getting additional material for their work.), the confined space should be re-tested .Before the worker re-enters. If the confined space has been continuously monitored by equipment that can show the details of the atmosphere during the time absent from the confined space and this information can be seen from outside the confined space, it can be re-entered without retesting. If there is not continuous air monitoring then the hazard assessment needs to be repeated.

Confined space should not be closed off until it has been verified that no person is inside it.

After exiting the confined space, the time of exit should be noted on the entry permit.

Checklist

| YES | NO | MONITORING |

|---|---|---|

| Will the atmosphere in the space be monitored while work is going on? | ||

| Continuously? | ||

| Periodically? | ||

| (If yes, give interval: …………….) |

REMEMBER – ATMOSPHERIC CHANGES OCCUR DUE TO THE WORK PROCEDURE OR THE PRODUCT STORED. THE ATMOSPHERE MAY BE SAFE WHEN YOU ENTER, BUT CAN CHANGE VERY QUICKLY.

What are some emergency response precautions?

If a situation arises where there is a hazardous condition and the worker does not leave or is unable to leave the confined space, rescue procedures should begin immediately.

The Safety Watch is qualified in confined spaces rescue procedures and will be available immediately outside the confined space for to provide emergency assistance if needed. The Safety Watch should be familiar with the structural design of the confined space. The Safety Watch is in constant communication with the worker inside the confined space and will:

- Have an alarm for calling for help.

- Have all required rescue equipment (for example, safety harnesses, lifting equipment, a lifeline) immediately available and be trained in its use.

- Hold a basic first aid certificate.

- Can do Cardiopulmonary Resuscitation (CPR).

The detailed plan for emergency response to an injury or other emergency within the confined space should be described in detail in the Confined Space Hazard Assessment and Control Programme.

Rescue the victims from outside of the confined space, if possible. No other worker should enter a confined space to attempt a rescue unless that worker is fully trained in the rescue procedures and is wearing the appropriate personal protective equipment. More than 60% of deaths in confined spaces are due to rescuers, who are not fully trained and adequately equipped.

Another worker qualified in confined spaces the rescue procedures must be present outside the confined space before the first rescuer enters the confined space. Do not use the same air as the workers in confined space you are rescuing. Wear SCBA (self contained breathing apparatus) or supplied air respirator with an escape bottle.

Checklist

| YES | NO | CLEANING |

|---|---|---|

| Has the space been cleaned before entry is made? | ||

| Was the space steamed? | ||

| If so, was it allowed to cool? |

| YES | NO | VENTILATION |

|---|---|---|

| Has the space been ventilated before entry? | ||

| Will ventilation be continued during entry? | ||

| Is the air intake for the ventilation system located in an area that is free of combustible dusts and vapors and toxic substances? | ||

| If atmosphere was found unacceptable and then ventilated, was it re-tested before entry? |

| YES | NO | ISOLATION |

|---|---|---|

| Has the space been isolated from other systems? | ||

| Has electrical equipment been locked out? | ||

| Have disconnects been used where possible? | ||

| Has mechanical equipment been blocked, chocked, and disengaged where necessary? | ||

| Have lines under pressure been blanked and bled? |

| YES | NO | CLOTHING/EQUIPMENT |

|---|---|---|

| Is special clothing required (boots, chemical suits, glasses. etc.)? (If so, specify:…………… ) |

||

| Is special equipment required (e.g. rescue equipment. communications equipment, etc.)? (If so, specify: ……………………………………) |

||

| Are special tools required (e.g., spark proof)? (If so, specify:……………………………. ) |

| YES | NO | RESPIRATORY PROTECTION |

|---|---|---|

| Are approved respirators of the type required available at the work site? | ||

| Is respiratory protection required (e.g., air-purifying, supplied air, self-contained breathing apparatus. etc.)? (If so, specify type:………………………………. ) |

||

| Can you get through the opening with a respirator on? (If you don’t know, find out before you try to enter.) |

Is worker training important?

Yes, appropriate training is extremely important to working safely in confined spaces. Hands-on training should be an essential part of the confined space training.

Every worker that enters a confined space must be fully trained on the following:

- Recognition and identification of potential hazards associated with the confined spaces that will be entered.

- Evaluation and control procedures for the identified or potential hazards.

- All equipment such as ventilation equipment (blowers), harnesses and air quality monitors (e.g., Oxygen/combustible meters) that will be used while in the confined space.

- All personal protective equipment (e.g., respirators) that the worker will be using while in the confined space.

- All procedures for entering the confined space as outlined in the employer’s Confined Space Hazard Assessment Programme.

- Procedures to follow in the event of a situation developing that could present additional risk to the worker or in emergency.

- The specific work to be done while in the confined space.

Workers with emergency rescue responsibilities will need additional specialized training. All confined space training should include some hands-on training with the safety equipment including the personal protective equipment and safety harnesses. Rescue procedures should be practiced frequently so there is a high level of proficiency. Employers should keep records of all confined spaces training including refresher courses.

Checklist

| YES | NO | TRAINING |

|---|---|---|

| Have you been trained in proper use of a respirator? | ||

| Have you received first aid/CPR training? | ||

| Have you been trained in confined space entry and do you know what to look for? |

What are other safety precautions?

Many other situations or hazards may be present in a confined space. Be sure that all hazards are controlled including:

- Any liquids or free-flowing solids are removed from the confined space to eliminate the risk of drowning or suffocation.

- All pipes should be physically disconnected or isolation blanks bolted in place.

- Closing valves is not sufficient.

- A barrier is present to prevent liquids or free-flowing solids from entering the confined space.

- The opening for entry into and exit from the confined space must be large enough to allow the passage of a person using protective equipment.

What is an Entry Permit System?

An Entry Permit is an administrative tool used to document the completion of a hazard assessment for each confined space entry. Someone fully trained and experienced in confined space work should complete the Entry Permit. Before entering a confined space, an entry permit should be written. It should contain at least the following information:

- The length of time the permit is valid for.

- The name(s) of the worker(s) that will enter the confined space.

- The name(s) of the attendant(s) (safety watch) and/or supervisor.

- The location of the confined space.

- The work that is to be done in the confined space.

- The date and time of entry into the confined space and the anticipated time of exit.

- The details of any atmospheric testing done of the confined space – when, where, results, date monitoring equipment was last calibrated. Ideally, calibration would be done just before each use. If this is not possible, follow the equipment manufacturers guidelines for frequency of calibration.

- The use of mechanical ventilation and other protective equipment needed and any other precautions that will be followed by every worker who is going to enter the confined space.

- The protective equipment and emergency equipment to be used by any person who takes part in a rescue or responds to other emergency situations in the confined space.

- A signature of a worker who did the confined space testing. The signature on the permit would indicate that adequate precautions are being taken to control the anticipated hazards.

- The entry permit should be posted at the confined space and remain so until the work is completed. The employer should keep a copy of the completed permit on file.

Standby/Rescue

A standby person should be assigned to remain on the outside of the confined space and be in constant contact (visual or speech) with the workers inside. The standby person should not have any other duties but to serve as standby and know who should be notified in case of emergency. Standby personnel should not enter a confined space until help arrives, and then only with proper protective equipment, life lines, and respirators.

Over 50% of the workers who die in confined spaces are attempting to rescue other workers. Rescuers must be trained in and follow established emergency procedures and use appropriate equipment and techniques (liftines, respiratory protection, standby persons, etc.). Steps for safe rescue should be included in all confined space entry procedures. Rescue should be well planned and drills should be frequently conducted on emergency procedures. Unplanned rescue, such as when someone instinctively rushes in to help a downed co-worker, can easily result in a double fatality, or even multiple fatalities if there are more than one would-be rescuers.

REMEMBER:

AN UNPLANNED RESCUE WILL PROBABLY BE YOUR LAST.

Checklist

| YES | NO | STANDBY/RESCUE |

|---|---|---|

| Will there be a standby person on the outside for constant visual or auditory communication with the person inside? | ||

| Will the standby person be able to see and/or hear the person inside at all times? | ||

| Has the standby person(s) been trained in rescue procedures? | ||

| Will safety lines and harness be required to remove a person? | ||

| Are company rescue procedures available to be followed in the event of an emergency? | ||

| Are you familiar with emergency rescue procedures? | ||

| Do you know who in to notify and how in the event of an emergency? |

| YES | NO | PERMIT |

|---|---|---|

| Has a confined space entry permit been issued? | ||

| Does the permit include a list of emergency telephone numbers? |

The permit is an authorization in writing that states that the space has been tested by a qualified person, that the space is safe for entry; what precautions, equipment, etc. are required ; and what work is to be done.

RECOMMENDATIONS FOR SAFE ENTRY: A CHECKLIST

Use the following checklist to evaluate the confined space.

DO NOT ENTER A CONFINED SPACE UNTIL YOU HAVE CONSIDERED EVERY QUESTION, AND HAVE DETERMINED THE SPACE TO BE SAFE.

| YES | NO | |

|---|---|---|

| Is entry necessary? |

| YES | NO | TESTING |

|---|---|---|

| Are the instruments used in atmospheric testing properly calibrated? | ||

| Was the atmosphere in the confined space tested? | ||

| Was Oxygen at least 19.5% – not more than 21%? | ||

| Were toxic, flammable, or oxygen-displacing gases/vapours present? |

| Which of the following gases are identified? | |

|---|---|

| Hydrogen Sulfide | |

| Carbon Monoxide | |

| Methane | |

| Carbon Dioxide | |

| Other (list) | |

| YES | NO | MONITORING |

|---|---|---|

| Will the atmosphere in the space be monitored while work is going on? | ||

| Continuously? | ||

| Periodically? | ||

| (If yes, give interval: …………….) |

REMEMBER – ATMOSPHERIC CHANGES OCCUR DUE TO THE WORK PROCEDURE OR THE PRODUCT STORED. THE ATMOSPHERE MAY BE SAFE WHEN YOU ENTER, BUT CAN CHANGE VERY QUICKLY.

| YES | NO | CLEANING |

|---|---|---|

| Has the space been cleaned before entry is made? | ||

| Was the space steamed? | ||

| If so, was it allowed to cool? |

| YES | NO | VENTILATION |

|---|---|---|

| Has the space been ventilated before entry? | ||

| Will ventilation be continued during entry? | ||

| Is the air intake for the ventilation system located in an area that is free of combustible dusts and vapors and toxic substances? | ||

| If atmosphere was found unacceptable and then ventilated, was it re-tested before entry? |

| YES | NO | ISOLATION |

|---|---|---|

| Has the space been isolated from other systems? | ||

| Has electrical equipment been locked out? | ||

| Have disconnects been used where possible? | ||

| Has mechanical equipment been blocked, chocked, and disengaged where necessary? | ||

| Have lines under pressure been blanked and bled? |

| YES | NO | CLOTHING/EQUIPMENT |

|---|---|---|

| Is special clothing required (boots, chemical suits, glasses. etc.)? (If so, specify:…………… ) |

||

| Is special equipment required (e.g. rescue equipment. communications equipment, etc.)? (If so, specify: ……………………………………) |

||

| Are special tools required (e.g., spark proof)? (If so, specify:……………………………. ) |

| YES | NO | RESPIRATORY PROTECTION |

|---|---|---|

| Are approved respirators of the type required available at the work site? | ||

| Is respiratory protection required (e.g., air-purifying, supplied air, self-contained breathing apparatus. etc.)? (If so, specify type:………………………………. ) |

||

| Can you get through the opening with a respirator on? (If you don’t know, find out before you try to enter.) |

| YES | NO | TRAINING |

|---|---|---|

| Have you been trained in proper use of a respirator? | ||

| Have you received first aid/CPR training? | ||

| Have you been trained in confined space entry and do you know what to look for? |

| YES | NO | STANDBY/RESCUE |

|---|---|---|

| Will there be a standby person on the outside for constant visual or auditory communication with the person inside? | ||

| Will the standby person be able to see and/or hear the person inside at all times? | ||

| Has the standby person(s) been trained in rescue procedures? | ||

| Will safety lines and harness be required to remove a person? | ||

| Are company rescue procedures available to be followed in the event of an emergency? | ||

| Are you familiar with emergency rescue procedures? | ||

| Do you know who in to notify and how in the event of an emergency? |

| YES | NO | PERMIT |

|---|---|---|

| Has a confined space entry permit been issued? | ||

| Does the permit include a list of emergency telephone numbers? |

The permit is an authorization in writing that states that the space has been tested by a qualified person, that the space is safe for entry; what precautions, equipment, etc. are required ; and what work is to be done.

For further information on confined spaces, occupational hazards, safe work practices, and other topics which could affect your well-being, write to or consult to chief inspector of factories of your state.

Glossary – Confined Space Safety

This glossary defines terms likely be encountered in material safety data sheets (MSDS).

- Acute: The effect caused by a single short term exposure to a high amount of concentration of a substance.

- Asphyxiation: A condition whereby oxygen in the is replaced by an inert gas such as nitrogen, carbon dioxide, ethane, hydrogen or helium to a level where it cannot sustain life. Normal air contains 21 percent of oxygen. If this concentration falls below about 17 percent, the human body tissue will be deprived of supply of oxygen, causing dizziness, nausea and loss of coordination. This type of situation may occur in confined work places.

- Auto-ignition temperature: The minimum temperature at which a material ignites without application or a flame.

- Chronic (health) effect: An adverse effect on a human body with symptoms development slowly over a long period of time.

- Chronic toxicity: A chronic effect resulting from repeated doses of or exposure to a substance over a relatively prolonged period of time.

- Confined space: Any area that has limited opening for entry or exit that would make escape difficult in an emergency, has a lack of ventilation, contains known and potential hazard, and is not normally intended or designed for continuous human occupancy (e.g. A storage tank, manhole of collection conveyances systems in effluent treatment plants.)

- Explosion proof-equipment: Apparatus or device enclosed in a case capable of withstanding an explosion of specified gas of vapor and preventing the ignition of specified gas or vapour surrounding the enclosure by spark, flash or explosion and operating at an external temperature so that surrounding flammable atmosphere will not be ignited.

- Flammable: A flammable liquid is defined as a liquid with a flash point between 21 and 55 degrees Celsius. It may catch fire on contact with a source of ignition.

- Flammable/explosion limits: Flammable / explosion limits produce a minimum and a maximum concentration of gases/vapours/fumes in air that will support combustion. The lowest concentration is known as the lower flammable/explosion limit (LEL), the highest concentration is know as upper flammable/explosion limit (UFL).

- Hazard: A potential to cause danger to life, health, property or the environment.

- Local exhaust: A system or device for capturing and exhausting contaminants from the air the point where the contaminants are produced (e.g. Dust in shaving and buffing).

- Poisoning: Normally the human body is able to cope with a variety of substances within certain limits. Poisoning occurs when these limits are exceeded and the body is unable to deal with a substance (by digestion, absorption or excretion).

- Risk: The measured probability of an event to cause danger to life, health, property or the environment.

- Toxicity: The inherent potential of a chemical substance to cause poisoning.

Jatin Dubey is a 26-year-old MBA student whose passion for storytelling and a deep love for literature have fueled his journey as an aspiring author. Born and raised in a small town, Jatin discovered the magic of words at a young age when he stumbled upon an old, dusty library tucked away in a forgotten corner of his neighborhood. As he delved into the world of books, he found solace and inspiration in the pages of classic novels and contemporary fiction.